![[Translate to English:] Logo HKM]( /fileadmin/user_upload/Referenzen/15Huettenwerke_Krupp_Mannesheim/0eb5b685725e5bfg0f7abc8690010925.jpg)

On the safe side with outdoor data center

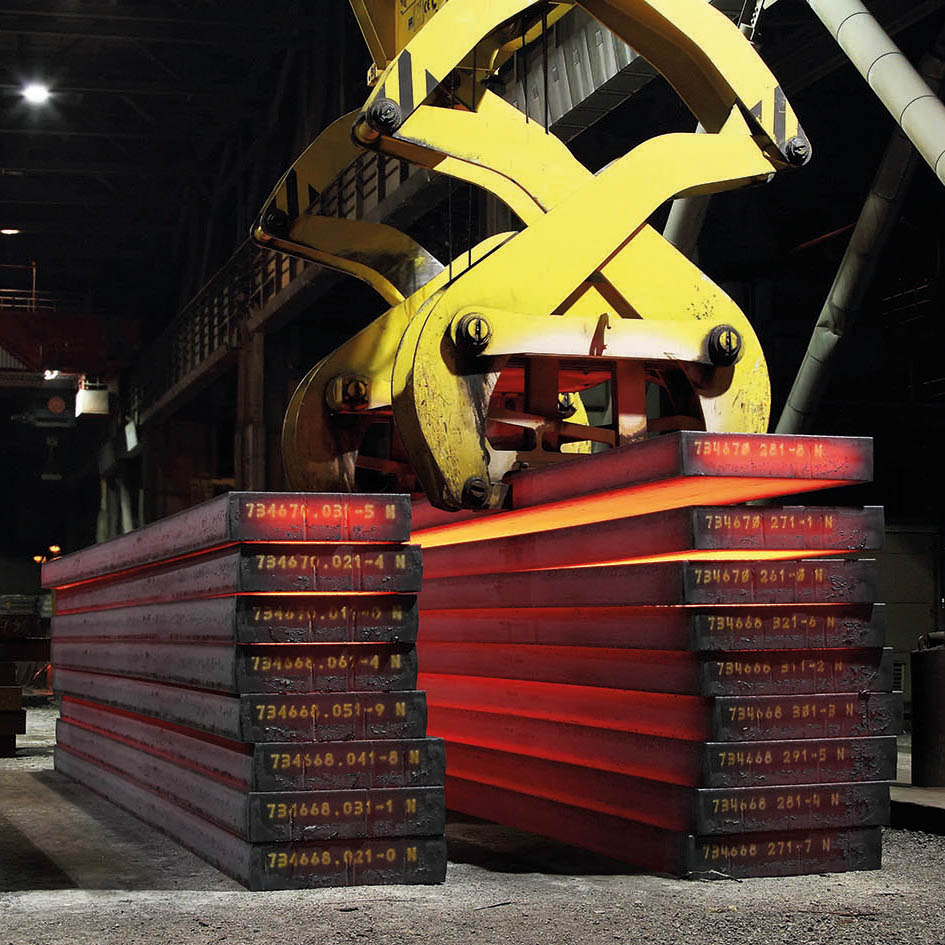

"Stahl. Das sind wir." Hüttenwerke Krupp Mannesmann (HKM) as an integrated ironworks stands for many years of experience and a comprehensive know-how. It is a modern steel company with technically and economically optimized production stages, working conditions, and environmental protection measures.

"Nowadays, the IT is more important for our company than ever. Even where there is seemingly no work done on computers, IT-systems control the respective processes from the background. The dependence on IT-availability is accordingly high", stresses Patrick Komfort, project manager at HKM. Data centers 1 and 2, which are redundant, were mostly responsible for this availability as Komfort says. However, if both failed, there would be a standstill. For several days in the worst case. Such a worst-case scenario could not to be ruled out because both data centers are only ten meters apart.

Events like a large fire in the maintenance or a crack in the clarifying basin on the other side of the street would have affected both data centers equally and brought the mill to a standstill. Hence, during the last months, the new data center X, which is closing this gap, was built and started operating on April 1st, 2019. HKM was looking for a reliable and competent partner for the construction of this data center and found the Data Center Group.

Even though the external view was important, Patrick Komfort did not solely rely on it. Instead, he chose a competent team and with the Data Center Group a reliable partner. Under careful consideration of all aspects, it was decided that the construction of a new data center was the most sensible solution because this way, costs would be reduced to a minimum in the midterm and risks permanently. “We settled to finish the new building until the end of 2018 and start operating April 1st, 2019”, says Patrick Komfort.

However, it was not as easily done as it seems. Unfortunately, in the IT-area (CI), the budget for a disaster recovery site was approved as an alternative center initially. It was supposed to take over the basic functions of the IT in the worst case. In fall 2017, Patrick Komfort became the new project manager. He had been at CI from 2004 until 2010 and has been working in controlling since 2010 for the area project management and basic issues. Hence, as a trained IT-specialist, business graduate and MBA, he is familiar with both worlds, the IT as well as controlling. He was an insider and was also able to look at things from the outside. Moreover, he was there when data center 2 was built in 2007 and knew: “Even back then, the close distance to data center 1 was not the ideal location, but it could not be realized on the mill in any other way.” An ambitious goal. After all, the preparation of the specifications and the tendering of the several crafts as well as the regulatory building permission were still pending. The final permission for the new building by the supervisory committee was only given at the end of the second quarterly period in 2018. Eventually, everything intertwined perfectly and even the building authority played along, as if it was part of the team. And since the Data Center Group, that was taken aboard in the middle of July 2018 as a general contractor, also signalized to finish in time, the starting signal for data center X was given October 8th, 2018. The Data Center Group had already constructed data center 2 and stayed in contact with HKM through the years so that HKM already knew they had a reliable and competent partner.

Facts and figure

Sales: Ralf Siefen

Project Management: Markus Böhmer

Data Center:

• IT-outdoor-container solution incl. crafts, 160 m²

• Performance in computer room 150 kW

• Propane-reciprocator chiller

• ESPS

• Gaseous extinguishing system

Duration of Construction: October 2018 until March 2019

The new data center stands exemplarily for the compatibility of established mill standards and modern industrial standards. Hence, the new building was built after the international data center standard DIN EN 50600 from 2016, is therefore absolutely fit for the future and reaches class three of four in the availability scale. “There are just two structural extensions missing to reach the highest class on the scale”, explains Patrick Komfort. However, there is already room for installing them later. The new building shows huge differences compared to the outdated precursor, data center 1, that was renovated in 1999. Both technically and in terms of security and energy efficiency. Thus, there is not a single 1-error-event that could lead to a breakdown in the computer room. Among others, this is because the new data center includes most things twice, e. g. the cooling technology, and because the data center is connected to the two network groups Mühlheim and Krefeld. Both would have to break down for the emergency power to turn on. And even that could keep the operation going for 48 hours.

Generally, data center X is well prepared for several scenarios with its broad output reserve. The high bandwidth is necessary regarding sustainability, just like everything in this new building is state-of-the-art. The 38 km long optical fibers, being installed throughout the entire mill, contribute to an interruption-free linkage of all HKM-areas to the new data center. That is also why most people did not notice much of the relocation from data center 1 into data center X. “It was almost completely noiseless”, says Patrick Komfort. The team reached their goal of building the best data center for HKM. Not least because of the fair and trustful cooperation with the Data Center Group and because the entire team, intern and extern, did so much more than what was expected and they really outdid themselves. All just to ensure that HKM will be on the safe side regarding IT-availability in the future.