Best4Tires is the experienced partner for both the tire industry and vehicle manufacturers. With decades of expertise in tires, rims and complete wheels, Best4Tires is one of the leading suppliers worldwide in this industry. Thanks to its in-house complete wheel production and perfect logistics, Best4Tires supplies workshops, car dealerships and tire dealers at the highest level.

Progress and innovation are among the company's core values. This includes not only the further development of the company-wide digital infrastructure, but also the digitalization of production, logistics and sales processes. Highly available and fail-safe IT infrastructures at the headquarters and the individual company locations form the basis for this.

However, the previous data center was no longer able to meet this requirements: Some of the components were already quite outdated and inefficient. The server room did not meet today's standards and was in an improper location. Reason enough to look for a new solution and the Daufenbach production and logistics site was chosen. Various options were to be evaluated: The room-in-room system within the production hall was quickly discarded, as the fire protection requirements are too high to implement economically due to the storage of rubber tires in the immediate proximity. Since there was still an open space available between the various production halls and warehouses at the site, there was great interest in a new outdoor data center. The DC IT Container as an all-in-one data center offered itself as a solution, since only minor structural measures are necessary for the foundation work and the data center can be set up completely pre-assembled. Cable shafts were already available at the desired location, which allowed direct access to the fiber optic cables.

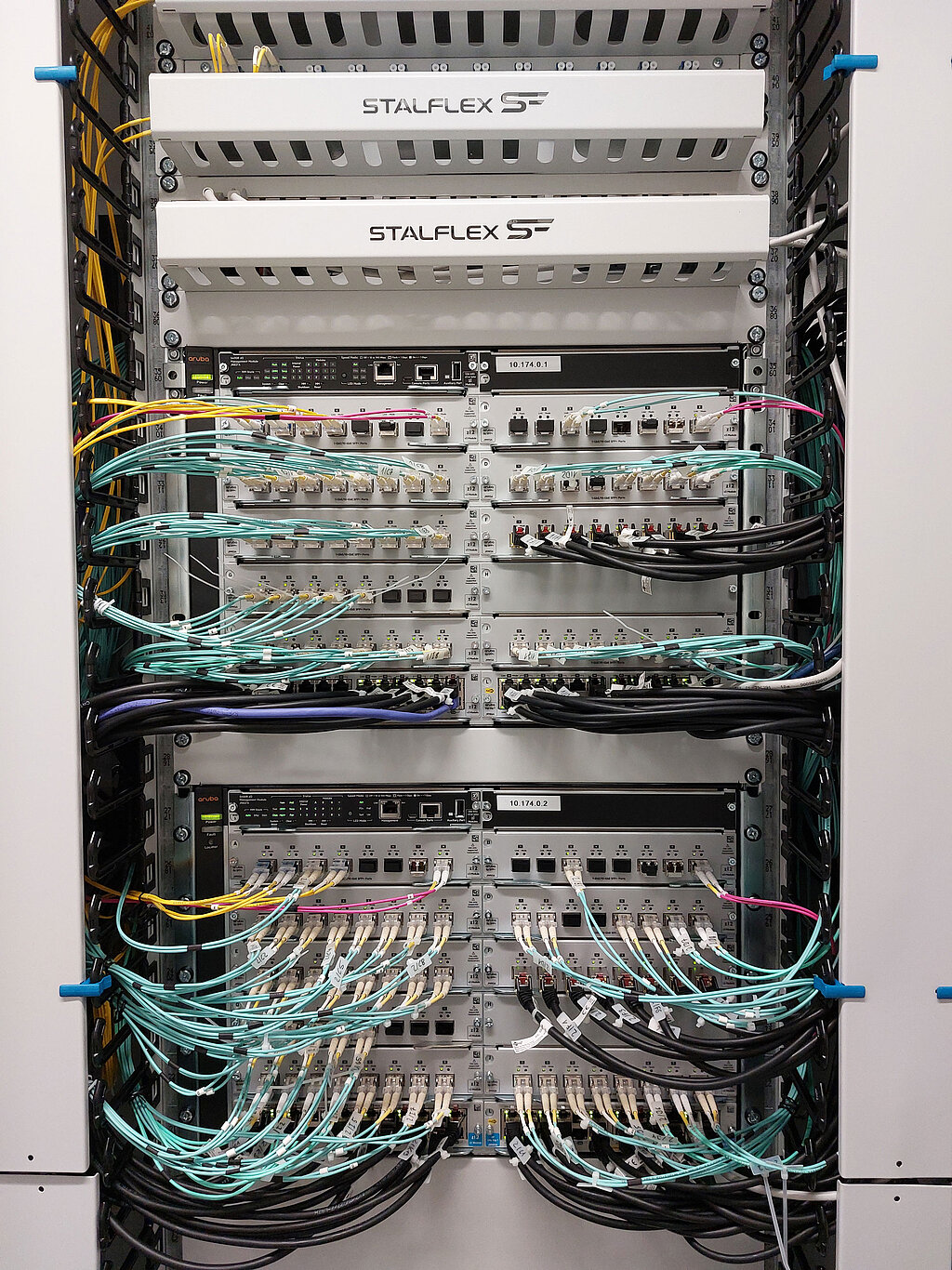

There was also a similar need for optimization at the inter-European branches: redundant and secure protection of the IT infrastructures was to be created. The production sites in Bratislava (Slovakia), Györ (Hungary) and Graz (Austria) each chose the Micro Data Center DC IT Safe as a low-latency edge solution.

Fail-safety and low latencies are particularly relevant for data processing at Best4Tires, as the production lines are completely digitally controlled. The individual components such as rims, tires and sensors are computer-controlled and fully automated in order to be delivered just-in-time or just-in-sequence to the corresponding plant of the car manufacturer.

"Production must be absolutely available in terms of IT. Downtime is not an option. This could mean that the car manufacturer's assembly line comes to a standstill because the corresponding parts for completion are missing. And every minute of downtime at the plant costs money. That's why we have built our IT infrastructures at all locations with complete redundancy. This means that the data centers are completely mirrored. If one system fails, the other can take over immediately," says Benjamin Uhr, Head of Infrastructure, Service and Support at Best4Tires. "We are very much 'on premises' oriented," he continues. "When communicating with the complete tire lines, we need very low latency, and we can't achieve that with a cloud-based solution. The server landscape for production needs fast communication through a short connection."

The Data Center Container at the Daufenbach logistics center is not only the digital heart of the Group. Among other things, the Sprinter fleet is also controlled from here. Guaranteed next-day delivery is made possible by smart Sprinter management of the company's own Sprinter fleet of 190 vehicles and a digital route planning system. Shipment tracking, delivery note creation and sign-off are also purely digital.

The constant availability of the data center is essential for route reconciliation, tour navigation and shipment data on the drivers' tablets. Benjamin Uhr summarizes: "Our business is heavily dependent on the functionality of the data center, which is why we didn't want to compromise on quality. That's why we opted for the high-quality and professional solution from Data Center Group."