Over the past ten years, inexio KGaA has become a champion in the niche market. The company, which now has around 220 employees, has built up a nationwide fiber optic network of more than 6,000 kilometers and supplies rural areas in particular with modern, high-performance telecommunications products. In addition to 65,000 residential customers, over 4,000 business customers also rely on inexio's expertise. They mostly benefit from the combination of pure telecommunications and Internet connectivity and the provision of highly available and secure data center capacities. Thanks to a direct fiber-optic connection through inexio, many companies have the technical opportunity for the first time to outsource data center services in a meaningful way and to use the quality of state-of-the-art data centers.

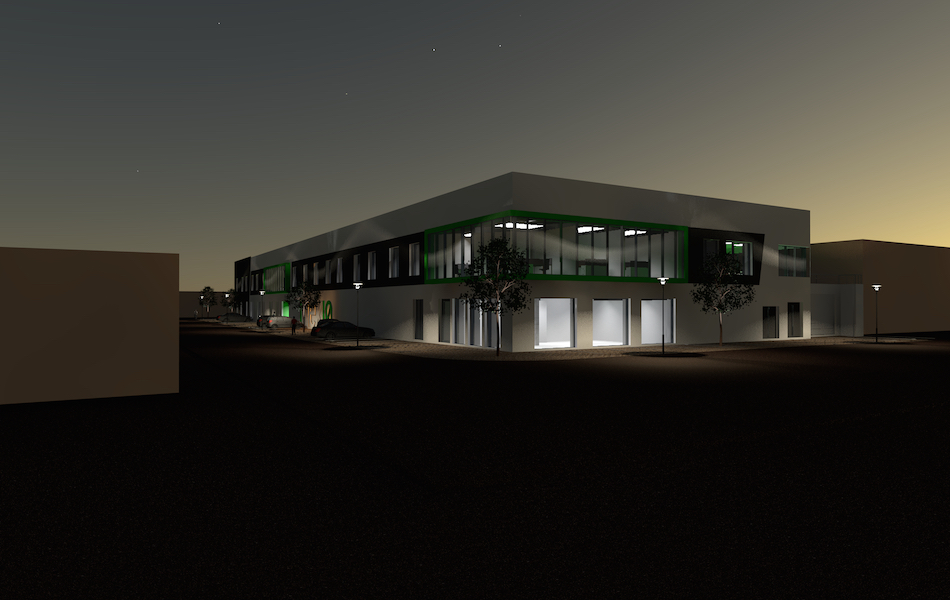

The Data Center Group has been acting as general contractor for inexio since 2011. During this time, five data centers and ten containers have been planned and implemented as indoor and outdoor solutions. Among other things, a large co-location data center has been built in Saarlouis, which has been certified by TÜV with Level 3 - this corresponds to the international standard TIER III. In addition to acting as a general contractor in the planning and construction phase, the Data Center Group is also active as a service provider for inexio - for example, in optimizing the data centers. inexio has decided to set up an energy management system instead of an annual energy audit. This involves recording all power consumers in inexio's data centers and visualizing them via a monitoring system.

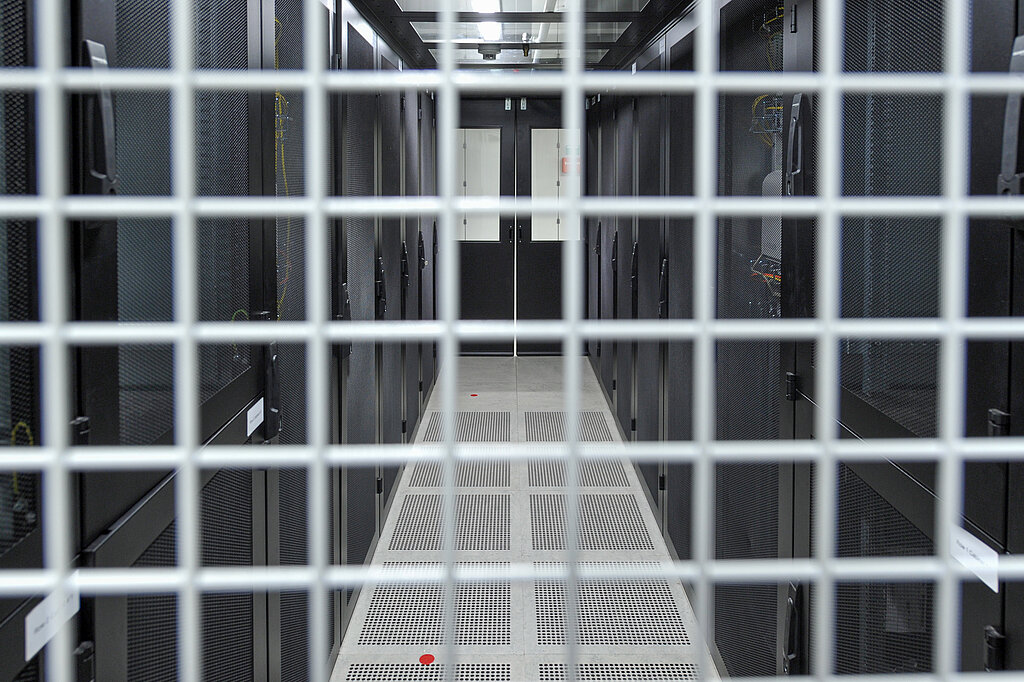

Currently, inexio had commissioned the Data Center Group's service business unit, Data Center Services, to optimize the partial and total PUE for the Einsiedlerhof data center site. The basis was a rough analysis of the air conditioning technology. On site, the possibilities for energy savings and thus cost savings were determined. Based on the calculations and the target/actual comparison, DCG calculated a savings potential of up to 31,000 kWh/a - at current energy costs, this results in annual cost savings in the high four-digit range. The return on investment for the necessary measures was achieved in ten months. The pure optimization work was carried out during ongoing operation of the data center. The Data Center Group used a high-resolution thermal imaging camera to check and record the maximum permissible cold aisle temperatures and the maximum permissible temperatures at the battery installation site.

"Security and cost efficiency are core values for us as a company. In my ongoing collaboration with the Data Center Group team, I experience that we act together according to these values. Added to this is a collegial - almost friendly - way of working together that is very pleasant."

Christian Würth Department Manager Data Centers inexio Informationstechnologie und Telekommunikation KGaA

Energy Savings

By measuring the power consumption of a climate control cabinet in the data center, it was possible to record the energy savings achieved by optimizing and converting the control system. On average, around 3.0 kWh of electrical power consumption is saved on the air-conditioning cabinets in the data center alone. Over the year, this corresponds to a reduction of 26,000 kWh and a reduction in CO2 emissions of around 13 tons. inexio also saves on ongoing energy costs. Since the optimization also enabled the chilled water temperature to be raised, free-cooling operation is also extended and DX operation is significantly more efficient. Significant additional savings can be expected here. This will be shown by an already agreed review of the partial PUE at the end of the year.

Conclusion: Through the consistent use of the thermal imaging camera, hotspots, missing bulkheads, incorrectly installed IT equipment, incorrect air routing and other optimization potentials are well identified and can be systematically corrected. The individual measures are recorded and logged so that they can be classified. The thermal imaging camera clearly shows where there is potential for energy savings and enables efficient implementation of the measures.