Tradition Meets Technology – A Family Business with High Standards

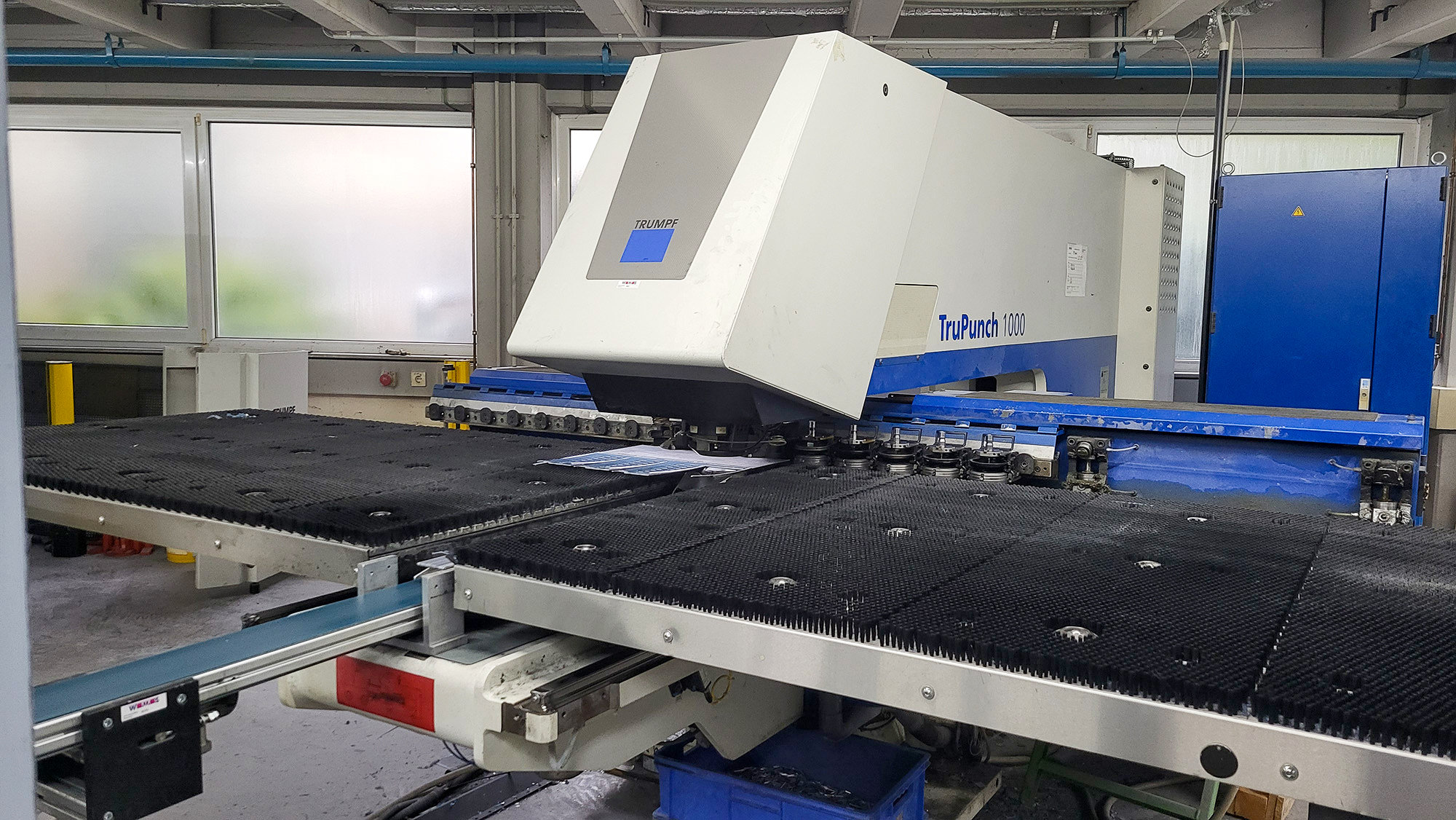

Ernst Wenzelmann Schilderfabrik GmbH is a traditional family-run company based in Unnau in the Westerwald region of Germany. Since its founding in 1953, it has been producing high-quality industrial and nameplates, technical labels, and panels made of aluminum, stainless steel, and technical plastics.

With around 40 employees and an annual turnover of approximately 4 million euros, the company- now in its third generation (grandfather Ernst, father Ernst Ludwig, and now son Dr.-Ing. Christoph Wenzelmann)- has been successfully manufacturing precision solutions for industrial applications.

As a manufacturing company with a modern machine park and highly digitalized processes, IT plays a central role. Nearly all business-critical operations depend on the company’s own server cluster-from production data collection and the ERP system to CAD-supported manufacturing.

Challenge: Aging Data Center Causing Downtime and High Maintenance Costs

The existing IT cabinet had been in operation for almost 20 years and was increasingly causing problems. Cooling failures, defective fans, and inefficient climate control led to disruptions and higher maintenance costs. Spare parts were difficult to obtain, and energy consumption was significantly higher than that of modern systems.

The goal was clear: to implement a compact, energy-efficient, and redundant IT security solution that would fit perfectly into the existing space and ensure continuous protection of the IT infrastructure-without any extended production downtime.

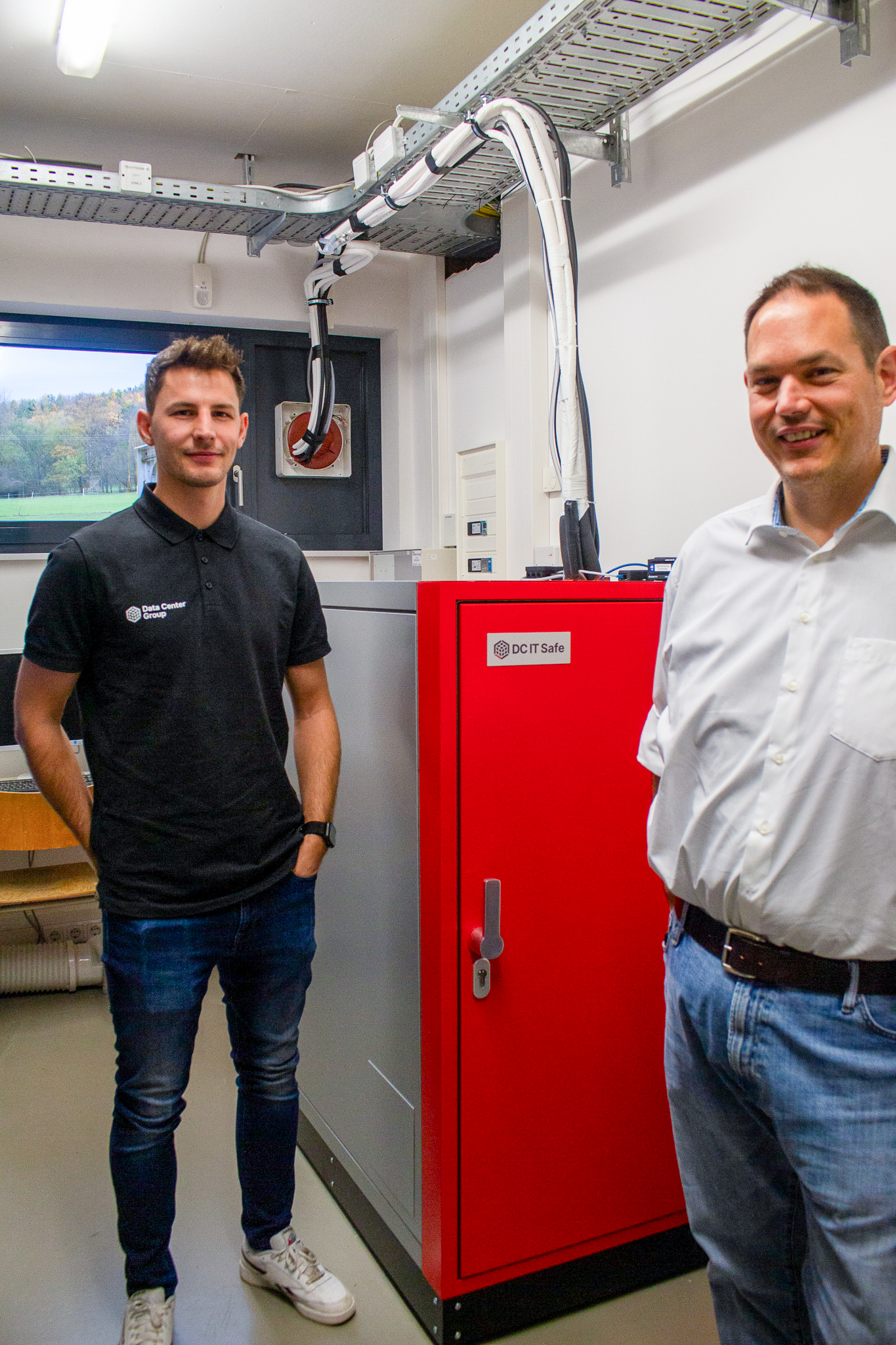

Solution: The DC IT Safe Mini from Data Center Group

While searching for a modern alternative, Ernst Wenzelmann Schilderfabrik came across the Data Center Group online. It quickly became clear that the DC IT Safe Mini was the ideal solution for the company’s needs.

The DC IT Safe Mini offers a compact, highly secure environment for servers, storage, and network equipment—providing protection against intrusion, moisture, and offering redundant cooling.

A key advantage is the separation between the indoor and outdoor units, which enables much more efficient cooling and reduces the thermal load in the room. After an on-site inspection, a customized concept was developed to perfectly match the spatial conditions.

Project Implementation: Precise Planning and Flexible Execution

The project began in spring 2025. Installation was scheduled for a Friday afternoon-a time when production is traditionally closed. This allowed the conversion to be carried out without interrupting production.

During installation, it became apparent that the originally planned position for the external units could not be implemented due to the wall structure. Thanks to the flexible and solution-oriented collaboration between the customer and the Data Center Group’s technicians, an alternative mounting position was quickly found.

This close on-site coordination ensured that the project was completed smoothly, on schedule, and within the planned budget.

Result: Stable IT Infrastructure, Less Effort, and Greater Efficiency

Since commissioning the DC IT Safe Mini, the system has been running stably, quietly, and reliably. The customer benefits from significantly improved operational reliability, efficient climate control, and modern digital monitoring. Through the monitoring interface, temperature trends and system status can be viewed and fine-tuned at any time—a level of convenience the previous system could not offer.

With the new cooling solution using separate indoor and outdoor units, the company also expects noticeable energy savings. The system operates far more efficiently than the old cooling unit, helping to reduce long-term operating costs.

Another advantage in daily IT operations: maintenance and faults are now a thing of the past. The system operates autonomously, allowing IT staff to focus once again on strategic tasks.

“A Fantastic Project from Start to Finish”

“I’m extremely satisfied. Everything worked perfectly—from the first contact to commissioning. I was particularly impressed by the flexibility of the on-site team—small issues were resolved immediately, and the project stayed on schedule. The DC IT Safe Mini runs stably, efficiently, and exactly as we had envisioned. I hardly have to worry about the IT infrastructure anymore, and the system is easy to monitor. Simply perfect.”

Dr.-Ing. Christoph Wenzelmann, Managing Director, Ernst Wenzelmann Schilderfabrik GmbH

Conclusion: Compact IT Security with a Future

With the installation of the DC IT Safe Mini, the Data Center Group provided Ernst Wenzelmann Schilderfabrik GmbH with a customized IT security solution that meets the highest standards for availability, energy efficiency, and operational reliability.

The project demonstrates how technical expertise, customer focus, and flexibility can create a future-proof IT environment-even under spatially demanding conditions.

Source pictures: Data Center Group