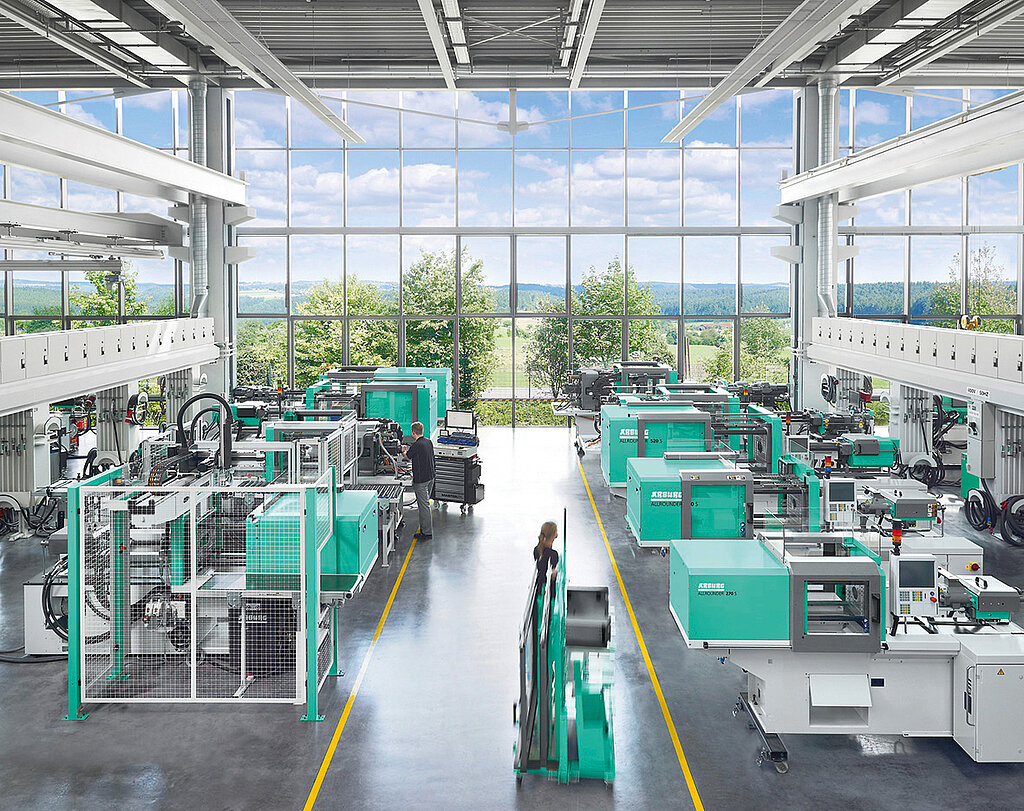

The German machine builder Arburg belongs to the leading machine builders for plastics processing worldwide. The company produces solely in Loßburg, Northern Black Forest, but it has locations all over the world. Among others, the product portfolio includes hydraulic, hybrid and electric injection molding machines and a system for additive manufacturing.

Arburg is a pioneer in production efficiency, industry 4.0 and digitalization in the international plastics branch. Security, efficiency and sustainability also take top priority for the company. Hence, Arburg was looking for an innovative and future-oriented solution for its new data center. The decision makers wanted to find a partner that understands company culture and values to offer an individual solution.

“We wanted all services to be from a single source to bring our data center up to date so we asked ourselves the question: Where are we and where do we want to be? This is a process which characterizes our entire company culture because we keep on evolving. And that is what we expect of our partners”, says Florian Schmitz, area manager building technology.

”We went deeply into the subject matter and diligently got information on the market,” adds Frank Himmelsbach, team leader communication and media. “During our research, we found the Data Center Group that quickly convinced us with the holistic concept its experts works with.” It all began with a risk analysis by Data Center Consulting, the consulting section of the Data Center Group. This analysis, conducted by a security expert, revealed optimizing potential in the IT-area.

Afterwards, measures were presented to improve both security and energy efficiency of Arburg’s IT-infrastructure. Another argument for the use of a DC IT Safe was that the reconstruction of existing data centers could happen quickly and without a lot of construction measures.

“The implementation of the project happened without any interruptions,“ says Himmelsbach about the process. “We got the best and at the same time a very individual solution for our company with the DC IT Safe,” he adds. “We were impressed by the quality of this miniature data center straight away. The new data center solution convinces with its quality made in Germany and offers the best possible protection for our IT.” “The cooperation with the Data Center Group was also very pleasant. It was an open, honest and target-oriented communication and the new data center is pointing the way ahead for our company,” summarizes Schmitz.

The solution which Arburg chose consists of four linked DC IT Safes by DC-Products GmbH. They offer the best protection in the smallest space and can always grow with the requirements of the Arburg-IT due to their modularity. An automatic fire detection and extinguishing system provides even more protection. The redundant cooling concept ensures constant ideal temperatures for the hardware inside the safe. If, however, the defined limit values for temperature or relative humidity were exceeded, the DC IT Monitoring agent DCM Agent would immediately send a fault report to the person in charge.

Facts

Project management: Frank Knoll

The data center:

DC IT Safe 62 U, 4-unit daisy-chaining

Redundant rack inverter cooling system ITS-DX-R, 4.9 -11.6 kW

Automatic fire alarm and fire extinguishing system

DC monitoring DCM Agent and DCM Extension

![[Translate to English:] [Translate to English:] Firmengebäude von Arburg. Eckih mit Grünfläche davor und Glaskonstruktion als Dekoration](/fileadmin/_processed_/3/a/csm_Arburg_Firmengebaeude_e7eb1dae8a.jpg) [Translate to English:]

[Translate to English:]